251,50 €*

Versandkostenfrei per Post / DHL

Aktuell nicht verfügbar

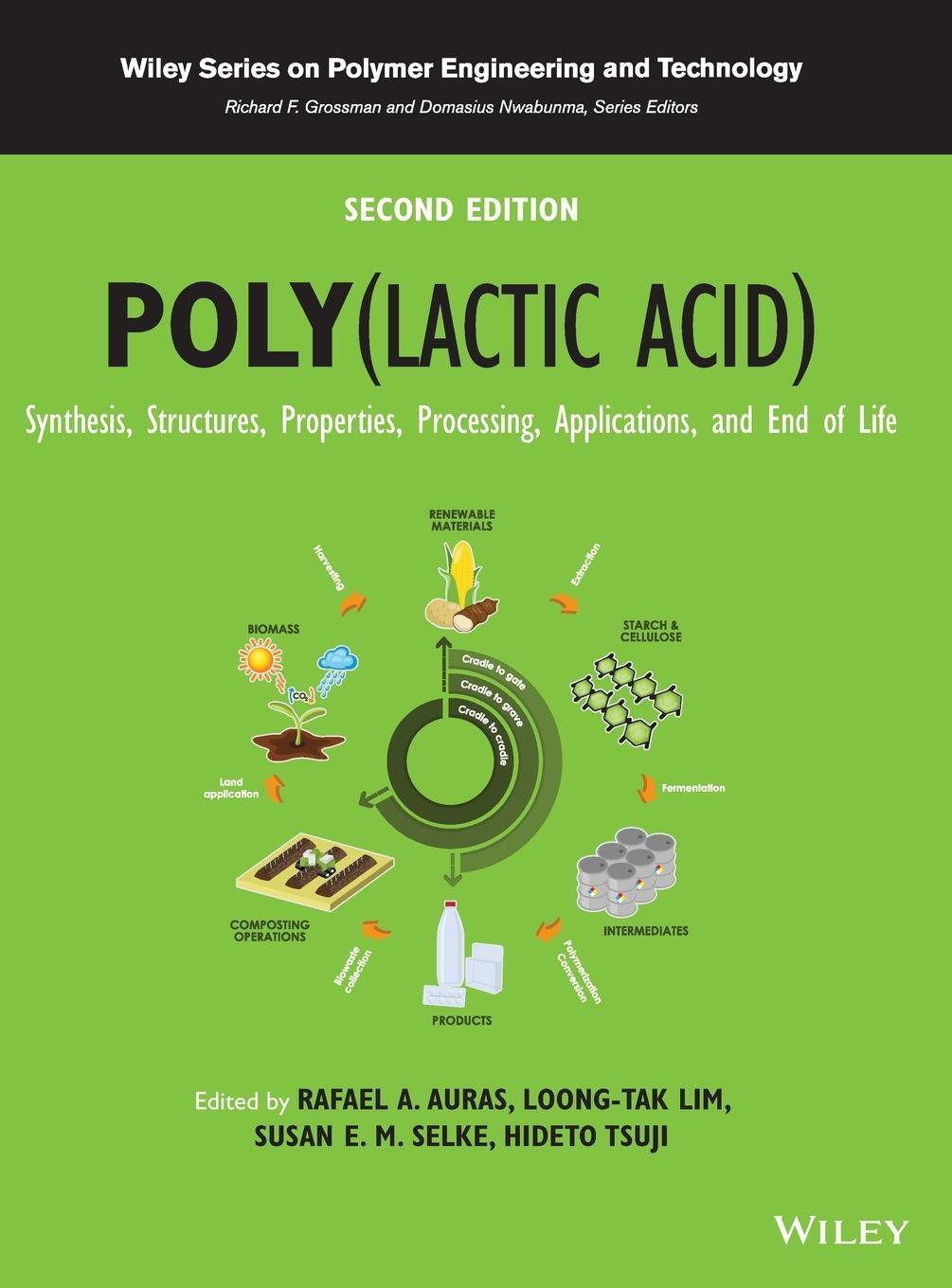

The second edition of a key reference, fully updated to reflect new research and applications

Poly(lactic acid)s - PLAs, biodegradable polymers derived from lactic acid, have become vital components of a sustainable society. Eco-friendly PLA polymers are used in numerous industrial applications ranging from packaging to medical implants and to wastewater treatment. The global PLA market is predicted to expand significantly over the next decade due to increasing demand for compostable and recyclable materials produced from renewable resources.

Poly(lactic acid) Synthesis, Structures, Properties, Processing, Applications, and End of Life provides comprehensive coverage of the basic chemistry, production, and industrial use of PLA. Contributions from an international panel of experts review specific processing methods, characterization techniques, and various applications in medicine, textiles, packaging, and environmental engineering. Now in its second edition, this fully up-to-date volume features new and revised chapters on 3D printing, the mechanical and chemical recycling of PLA, PLA stereocomplex crystals, PLA composites, the environmental footprint of PLA, and more.

* Highlights the biodegradability, recycling, and sustainability benefits of PLA

* Describes processing and conversion technologies for PLA, such as injection molding, extrusion, blending, and thermoforming

* Covers various aspects of lactic acid/lactide monomers, including physicochemical properties and production

* Examines different condensation reactions and modification strategies for enhanced polymerization of PLA

* Discusses the thermal, rheological, and mechanical properties of PLA

* Addresses degradation and environmental issues of PLA, including photodegradation, radiolysis, hydrolytic degradation, biodegradation, and life cycle assessment

Poly(lactic acid) Synthesis, Structures, Properties, Processing, Applications, and End of Life, Second Edition remains essential reading for polymer engineers, materials scientists, polymer chemists, chemical engineers, industry professionals using PLA, and scientists and advanced student engineers interested in biodegradable plastics.

The second edition of a key reference, fully updated to reflect new research and applications

Poly(lactic acid)s - PLAs, biodegradable polymers derived from lactic acid, have become vital components of a sustainable society. Eco-friendly PLA polymers are used in numerous industrial applications ranging from packaging to medical implants and to wastewater treatment. The global PLA market is predicted to expand significantly over the next decade due to increasing demand for compostable and recyclable materials produced from renewable resources.

Poly(lactic acid) Synthesis, Structures, Properties, Processing, Applications, and End of Life provides comprehensive coverage of the basic chemistry, production, and industrial use of PLA. Contributions from an international panel of experts review specific processing methods, characterization techniques, and various applications in medicine, textiles, packaging, and environmental engineering. Now in its second edition, this fully up-to-date volume features new and revised chapters on 3D printing, the mechanical and chemical recycling of PLA, PLA stereocomplex crystals, PLA composites, the environmental footprint of PLA, and more.

* Highlights the biodegradability, recycling, and sustainability benefits of PLA

* Describes processing and conversion technologies for PLA, such as injection molding, extrusion, blending, and thermoforming

* Covers various aspects of lactic acid/lactide monomers, including physicochemical properties and production

* Examines different condensation reactions and modification strategies for enhanced polymerization of PLA

* Discusses the thermal, rheological, and mechanical properties of PLA

* Addresses degradation and environmental issues of PLA, including photodegradation, radiolysis, hydrolytic degradation, biodegradation, and life cycle assessment

Poly(lactic acid) Synthesis, Structures, Properties, Processing, Applications, and End of Life, Second Edition remains essential reading for polymer engineers, materials scientists, polymer chemists, chemical engineers, industry professionals using PLA, and scientists and advanced student engineers interested in biodegradable plastics.

RAFAEL A. AURAS, Professor, School of Packaging, College of Agriculture & Natural Resources, Michigan State University, USA.

LOONG-TAK LIM, Professor, Department of Food Science, University of Guelph, Canada.

SUSAN E. M. SELKE, Professor Emeritus, School of Packaging, College of Agriculture & Natural Resources, Michigan State University, USA.

HIDETO TSUJI, Professor, Department of Applied Chemistry and Life Science, Toyohashi University of Technology, Japan.

Preface xxiii

Author Biographies xxvii

Part I Chemistry and Production of Lactic Acid, Lactide, and Poly(Lactic Acid) 1

1 Production and Purification of Lactic Acid and Lactide 3

Wim Groot, Jan van Krieken, Olav Sliekersl, and Sicco de Vos

1.1 Introduction 3

1.2 Lactic Acid 4

1.2.1 History of Lactic Acid 4

1.2.2 Physical Properties of Lactic Acid 4

1.2.3 Chemistry of Lactic Acid 4

1.2.4 Production of Lactic Acid by Fermentation 5

1.2.5 Downstream Processing/Purification of Lactic Acid 8

1.2.6 Quality/Specifications of Lactic Acid 10

1.3 Lactide 10

1.3.1 Physical Properties of Lactide 10

1.3.2 Production of Lactide 11

1.3.3 Purification of Lactide 13

1.3.4 Quality and Specifications of Polymer-Grade Lactide 14

1.3.5 Concluding Remarks on Polymer-Grade Lactide 16

References 16

2 Aqueous Solutions of Lactic Acid 19

Carl T. Lira and Lars Peereboom

2.1 Introduction 19

2.2 Structure of Lactic Acid 19

2.3 Vapor Pressure of Anhydrous Lactic Acid and Lactide 19

2.4 Oligomerization in Aqueous Solutions 20

2.5 Equilibrium Distribution of Oligomers 21

2.6 Vapor-Liquid Equilibrium 23

2.7 Density of Aqueous Solutions 25

2.8 Viscosity of Aqueous Solutions 25

2.9 Summary 26

References 26

3 Industrial Production of High-Molecular-Weight Poly(Lactic Acid) 29

Anders Södergård, Mikael Stolt, and Saara Inkinen

3.1 Introduction 29

3.2 Lactic-Acid-Based Polymers by Polycondensation 30

3.2.1 Direct Condensation 31

3.2.2 Solid-State Polycondensation 32

3.2.3 Azeotropic Dehydration 33

3.3 Lactic Acid-Based Polymers by Chain Extension 34

3.3.1 Chain Extension with Diisocyanates 34

3.3.2 Chain Extension with Bis-2-Oxazoline 36

3.3.3 Dual Linking Processes 36

3.3.4 Chain Extension with Bis-Epoxies 36

3.4 Lactic-Acid-Based Polymers by Ring-Opening Polymerization 37

3.4.1 Polycondensation Processes 37

3.4.2 Lactide Manufacturing 37

3.4.3 Ring-Opening Polymerization 39

References 40

4 Design and Synthesis of Different Types of Poly(Lactic Acid)/Polylactide Copolymers 45

Ann-Christine

Albertsson, Indra Kumari Varma, Bimlesh Lochab, Anna Finne-Wistrand, Sangeeta Sahu, and Kamlesh Kumar

4.1 Introduction 45

4.2 Comonomers with Lactic Acid/Lactide 47

4.2.1 Glycolic Acid/Glycolide 47

4.2.2 Poly(Alkylene Glycol) 48

4.2.3 delta-Valerolactone and ß-Butyrolactone 51

4.2.4 epsilon-Caprolactone 51

4.2.5 1,5-Dioxepan-2-One 52

4.2.6 Trimethylene Carbonate 52

4.2.7 Poly(N-Isopropylacrylamide) 52

4.2.8 Alkylthiophene (P3AT) 53

4.2.9 Polypeptide 53

4.3 Functionalized PLA 54

4.4 Macromolecular Design of Lactide-Based Copolymers 55

4.4.1 Graft Copolymers 57

4.4.2 Star-Shaped Copolymers 59

4.4.3 Periodic Copolymers 60

4.5 Properties of Lactide-Based Copolymers 62

4.6 Degradation of Lactide Homo-and Copolymers 63

4.6.1 Drug Delivery from Lactide-Based Copolymers 64

4.6.2 Radiation Effects 65

References 65

5 Preparation, Structure, and Properties of Stereocomplex-Type Poly(Lactic Acid) 73

Neha Mulchandani, Yoshiharu Kimura, and Vimal Katiyar

5.1 Introduction 73

5.2 Stereocomplexation in Poly(Lactic Acid) 73

5.3 Crystal Structure of sc-PLA 74

5.4 Formation of Stereoblock PLA 75

5.4.1 Single-Step Process 75

5.4.2 Stepwise ROP 76

5.4.3 Chain Coupling Method 77

5.5 Stereocomplexation in Copolymers 79

5.5.1 Stereocomplexation in Random and Alternating Lactic Acid or Lactide-Based Polymers 79

5.5.2 sc-PLA-PCL Copolymers 80

5.5.3 sc-PLA-PEG Copolymers 80

5.6 Stereocomplex PLA-Based Composites 81

5.7 Advances in Stereocomplex-PLA 82

5.8 Conclusions 83

References 83

Part II Properties 87

6 Structures and Phase Transitions of PLA and Its Related Polymers 89

Hai Wang and Kohji Tashiro

6.1 Introduction 89

6.2 Structural Study of PLA 89

6.2.1 Preparation of Crystal Modifications of PLA 89

6.2.2 Crystal Structure of the alpha Form 91

6.2.3 Crystal Structure of the delta Form 92

6.2.4 Crystal Structure of the ß Form 93

6.2.5 Structure of the Mesophase 94

6.3 Thermally Induced Phase Transitions 95

6.3.1 Phase Transition in Cold Crystallization 95

6.3.2 Phase Transition in the Melt Crystallization 95

6.3.3 Mechanically Induced Phase Transition 96

6.4 Microscopically-viewed Structure-Mechanical Properties of PLA 98

6.5 Structure and Formation of PLLA/PDLA Stereocomplex 100

6.5.1 Reconsideration of the Crystal Structure 100

6.5.2 Experimental Support of P3 Structure Model 103

6.5.3 Formation Mechanism of Stereocomplex 104

6.6 PHB and Other Biodegradable Polyesters 106

6.6.1 Poly(3-Hydroxybutyrate) (PHB) 106

6.6.2 Polyethylene Adipate (PEA) 109

6.7 Future Perspectives 110

Acknowledgements 110

References 110

7 Optical and Spectroscopic Properties 115

Isabel M. Marrucho

7.1 Introduction 115

7.2 Absorption and Transmission of UV-Vis Radiation 115

7.3 Refractive Index 118

7.4 Specific Optical Rotation 119

7.5 Infrared and Raman Spectroscopy 119

7.5.1 Infrared Spectroscopy 120

7.5.2 Raman Spectroscopy 125

7.6 1H and 13C NMR Spectroscopy 127

References 131

8 Crystallization and Thermal Properties 135

Luca Fambri and Claudio Migliaresi

8.1 Introduction 135

8.2 Crystallinity and Crystallization 136

8.3 Crystallization Regime 140

8.4 Fibers 142

8.5 Commercial Polymers and Products 144

8.6 Degradation and Crystallinity 146

Acknowledgments 148

References 148

9 Rheology of Poly(Lactic Acid) 153

John R. Dorgan

9.1 Introduction 153

9.2 Fundamental Chain Properties from Dilute Solution Viscometry 154

9.2.1 Unperturbed Chain Dimensions 154

9.2.2 Real Chains 154

9.2.3 Solution Viscometry 155

9.2.4 Viscometry of PLA 156

9.3 Processing of PLA: General Considerations 158

9.4 Melt Rheology: An Overview 159

9.5 Processing of PLA: Rheological Properties 160

9.6 Conclusions 165

Appendix 9.A Description of the Software 166

References 166

10 Mechanical Properties 169

Mohammadreza Nofar, Gabriele Perego, and Gian Domenico Cella

10.1 Introduction 169

10.2 General Mechanical Properties and Molecular Weight Effect 170

10.2.1 Tensile and Flexural Properties 170

10.2.2 Impact Resistance 171

10.2.3 Hardness 172

10.3 Temperature Effect 172

10.4 Relaxation and Aging 173

10.5 Annealing 174

10.6 Orientation 176

10.7 Stereoregularity 179

10.8 Self-Reinforced

PLA Composites 180

10.9 PLA Nanocomposites 180

10.10 Copolymerization 181

10.11 Plasticization 181

10.12 PLA Blends 182

10.13 Conclusions 186

References 186

11 Mass Transfer 191

Uruchaya Sonchaeng and Rafael Auras

11.1 Introduction 191

11.2 Background on Mass Transfer in Polymers 193

11.3 Mass Transfer Properties of Neat PLA Films 194

11.3.1 Mass Transfer of Gases 194

11.3.2 Mass Transfer of Oxygen 199

11.3.3 Mass Transfer of Water Vapor 201

11.3.4 Mass Transfer of Organic Vapors 203

11.4 Mass Transfer Properties of Modified PLA 205

11.4.1 PLA Stereocomplex and PLA Blends 206

11.4.2 PLA Nanocomposites 207

11.4.3 Other PLA Modifications 207

11.4.4 PLA in Other Forms 207

11.5 Final Remarks 208

Acknowledgments 208

References 208

12 Migration and Interaction with Contact Materials 217

Herlinda Soto-Valdez and Elizabeth Peralta

12.1 Introduction 217

12.2 Migration Principles 217

12.3 Legislation 218

12.4 Migration and Toxicological Data of Lactic Acid, Lactide, Dimers, and Oligomers 219

12.4.1 Lactic Acid 219

12.4.2 Lactide 224

12.4.3 Oligomers 225

12.5 EDI of Lactic Acid 226

12.6 Other Potential Migrants from PLA 227

12.7 Conclusions 227

References 228

Part III Processing and Conversion 231

13 Processing of Poly(Lactic Acid) 233

Loong-Tak Lim, Tim Vanyo, Jed Randall, Kevin Cink, and Ashwini K. Agrawal

13.1 Introduction 233

13.2 Properties of PLA Relevant to Processing 233

13.3 Modification of PLA Properties by Process Aids and Other Additives 235

13.4 Drying and Crystallizing 237

13.5 Extrusion 239

13.6 Injection Molding 241

13.7 Film and Sheet Casting 245

13.8 Stretch Blow Molding 249

13.9 Extrusion Blown Film 251

13.10 Thermoforming 252

13.11 Melt Spinning 254

13.12 Solution Spinning 258

13.13 Electrospinning 261

13.14 Filament Extrusion and 3D-Printing 265

13.15 Conclusion: Prospects of PLA Polymers 266

References 267

14 Blends 271

Ajay Kathuria, Sukeewan Detyothin, Waree Jaruwattanayon, Susan E. M. Selke, and Rafael Auras

14.1 Introduction 271

14.2 PLA Nonbiodegradable Polymer Blends 272

14.2.1 Polyolefins 272

14.2.2 Vinyl and Vinylidene Polymers and Copolymers 279

14.2.3 Rubbers and Elastomers 285

14.2.4 PLA/PMMA Blends 287

14.3 PLA/Biodegradable Polymer Blends 289

14.3.1 Polyanhydrides 289

14.3.2 Vinyl and Vinylidene Polymers and Copolymers 289

14.3.3 Aliphatic Polyesters and Copolyesters 297

14.3.4 Aliphatic-Aromatic Copolyesters 303

14.3.5 Elastomers and Rubbers 305

14.3.6 Poly(Ester Amide)/PLA Blends 307

14.3.7 Polyethers and Copolymers 307

14.3.8 Annually Renewable Biodegradable Materials 309

14.4 Plasticization of PLA 322

14.5 Conclusions 326

References 327

15 Foaming 341

Laurent M. Matuana

15.1 Introduction 341

15.2 Plastic Foams 341

15.3 Foaming Agents 342

15.3.1 Physical Foaming Agents 342

15.3.2 Chemical Foaming Agents 342

15.4 Formation of Cellular Plastics 343

15.4.1 Dissolution of Blowing Agent in Polymer 343

15.4.2 Bubble Formation 343

15.4.3 Bubble Growth and Stabilization 344

15.5 Plastic Foams Expanded with Physical Foaming Agents 344

15.5.1 Microcellular Foamed Polymers 344

15.5.2 Solid-State Batch Microcellular Foaming Process 345

15.5.3 Microcellular Foaming in a Continuous Process 353

15.6 PLA Foamed with Chemical Foaming Agents 358

15.6.1 Effects of CFA Content and Type 358

15.6.2 Effect of Processing Conditions 359

15.7 Mechanical Properties of PLA Foams 360

15.7.1 Batch Microcellular Foamed PLA 360

15.7.2 Extrusion of PLA 361

15.7.3 Microcellular Injection Molding of PLA 362

15.8 Foaming of PLA/Starch and Other Blends 362

References 363

16 Composites 367

Tanmay Gupta, Vijay Shankar Kumawat, Subrata Bandhu Ghosh, Sanchita Bandyopadhyay-Ghosh, and Mohini Sain

16.1...

| Erscheinungsjahr: | 2022 |

|---|---|

| Fachbereich: | Allgemeines |

| Genre: | Chemie |

| Rubrik: | Naturwissenschaften & Technik |

| Medium: | Buch |

| Seiten: | 688 |

| Inhalt: | 688 S. |

| ISBN-13: | 9781119767442 |

| ISBN-10: | 111976744X |

| Sprache: | Englisch |

| Einband: | Gebunden |

| Autor: | Auras, Rafael A. |

| Redaktion: |

Auras, Rafael A

Lim, Loong-Tak Selke, Susan E M Tsuji, Hideto |

| Herausgeber: | Rafael A Auras/Loong-Tak Lim/Susan E M Selke et al |

| Auflage: | 2nd edition |

| Hersteller: | Wiley |

| Maße: | 286 x 221 x 41 mm |

| Von/Mit: | Rafael A Auras (u. a.) |

| Erscheinungsdatum: | 21.06.2022 |

| Gewicht: | 1,968 kg |

RAFAEL A. AURAS, Professor, School of Packaging, College of Agriculture & Natural Resources, Michigan State University, USA.

LOONG-TAK LIM, Professor, Department of Food Science, University of Guelph, Canada.

SUSAN E. M. SELKE, Professor Emeritus, School of Packaging, College of Agriculture & Natural Resources, Michigan State University, USA.

HIDETO TSUJI, Professor, Department of Applied Chemistry and Life Science, Toyohashi University of Technology, Japan.

Preface xxiii

Author Biographies xxvii

Part I Chemistry and Production of Lactic Acid, Lactide, and Poly(Lactic Acid) 1

1 Production and Purification of Lactic Acid and Lactide 3

Wim Groot, Jan van Krieken, Olav Sliekersl, and Sicco de Vos

1.1 Introduction 3

1.2 Lactic Acid 4

1.2.1 History of Lactic Acid 4

1.2.2 Physical Properties of Lactic Acid 4

1.2.3 Chemistry of Lactic Acid 4

1.2.4 Production of Lactic Acid by Fermentation 5

1.2.5 Downstream Processing/Purification of Lactic Acid 8

1.2.6 Quality/Specifications of Lactic Acid 10

1.3 Lactide 10

1.3.1 Physical Properties of Lactide 10

1.3.2 Production of Lactide 11

1.3.3 Purification of Lactide 13

1.3.4 Quality and Specifications of Polymer-Grade Lactide 14

1.3.5 Concluding Remarks on Polymer-Grade Lactide 16

References 16

2 Aqueous Solutions of Lactic Acid 19

Carl T. Lira and Lars Peereboom

2.1 Introduction 19

2.2 Structure of Lactic Acid 19

2.3 Vapor Pressure of Anhydrous Lactic Acid and Lactide 19

2.4 Oligomerization in Aqueous Solutions 20

2.5 Equilibrium Distribution of Oligomers 21

2.6 Vapor-Liquid Equilibrium 23

2.7 Density of Aqueous Solutions 25

2.8 Viscosity of Aqueous Solutions 25

2.9 Summary 26

References 26

3 Industrial Production of High-Molecular-Weight Poly(Lactic Acid) 29

Anders Södergård, Mikael Stolt, and Saara Inkinen

3.1 Introduction 29

3.2 Lactic-Acid-Based Polymers by Polycondensation 30

3.2.1 Direct Condensation 31

3.2.2 Solid-State Polycondensation 32

3.2.3 Azeotropic Dehydration 33

3.3 Lactic Acid-Based Polymers by Chain Extension 34

3.3.1 Chain Extension with Diisocyanates 34

3.3.2 Chain Extension with Bis-2-Oxazoline 36

3.3.3 Dual Linking Processes 36

3.3.4 Chain Extension with Bis-Epoxies 36

3.4 Lactic-Acid-Based Polymers by Ring-Opening Polymerization 37

3.4.1 Polycondensation Processes 37

3.4.2 Lactide Manufacturing 37

3.4.3 Ring-Opening Polymerization 39

References 40

4 Design and Synthesis of Different Types of Poly(Lactic Acid)/Polylactide Copolymers 45

Ann-Christine

Albertsson, Indra Kumari Varma, Bimlesh Lochab, Anna Finne-Wistrand, Sangeeta Sahu, and Kamlesh Kumar

4.1 Introduction 45

4.2 Comonomers with Lactic Acid/Lactide 47

4.2.1 Glycolic Acid/Glycolide 47

4.2.2 Poly(Alkylene Glycol) 48

4.2.3 delta-Valerolactone and ß-Butyrolactone 51

4.2.4 epsilon-Caprolactone 51

4.2.5 1,5-Dioxepan-2-One 52

4.2.6 Trimethylene Carbonate 52

4.2.7 Poly(N-Isopropylacrylamide) 52

4.2.8 Alkylthiophene (P3AT) 53

4.2.9 Polypeptide 53

4.3 Functionalized PLA 54

4.4 Macromolecular Design of Lactide-Based Copolymers 55

4.4.1 Graft Copolymers 57

4.4.2 Star-Shaped Copolymers 59

4.4.3 Periodic Copolymers 60

4.5 Properties of Lactide-Based Copolymers 62

4.6 Degradation of Lactide Homo-and Copolymers 63

4.6.1 Drug Delivery from Lactide-Based Copolymers 64

4.6.2 Radiation Effects 65

References 65

5 Preparation, Structure, and Properties of Stereocomplex-Type Poly(Lactic Acid) 73

Neha Mulchandani, Yoshiharu Kimura, and Vimal Katiyar

5.1 Introduction 73

5.2 Stereocomplexation in Poly(Lactic Acid) 73

5.3 Crystal Structure of sc-PLA 74

5.4 Formation of Stereoblock PLA 75

5.4.1 Single-Step Process 75

5.4.2 Stepwise ROP 76

5.4.3 Chain Coupling Method 77

5.5 Stereocomplexation in Copolymers 79

5.5.1 Stereocomplexation in Random and Alternating Lactic Acid or Lactide-Based Polymers 79

5.5.2 sc-PLA-PCL Copolymers 80

5.5.3 sc-PLA-PEG Copolymers 80

5.6 Stereocomplex PLA-Based Composites 81

5.7 Advances in Stereocomplex-PLA 82

5.8 Conclusions 83

References 83

Part II Properties 87

6 Structures and Phase Transitions of PLA and Its Related Polymers 89

Hai Wang and Kohji Tashiro

6.1 Introduction 89

6.2 Structural Study of PLA 89

6.2.1 Preparation of Crystal Modifications of PLA 89

6.2.2 Crystal Structure of the alpha Form 91

6.2.3 Crystal Structure of the delta Form 92

6.2.4 Crystal Structure of the ß Form 93

6.2.5 Structure of the Mesophase 94

6.3 Thermally Induced Phase Transitions 95

6.3.1 Phase Transition in Cold Crystallization 95

6.3.2 Phase Transition in the Melt Crystallization 95

6.3.3 Mechanically Induced Phase Transition 96

6.4 Microscopically-viewed Structure-Mechanical Properties of PLA 98

6.5 Structure and Formation of PLLA/PDLA Stereocomplex 100

6.5.1 Reconsideration of the Crystal Structure 100

6.5.2 Experimental Support of P3 Structure Model 103

6.5.3 Formation Mechanism of Stereocomplex 104

6.6 PHB and Other Biodegradable Polyesters 106

6.6.1 Poly(3-Hydroxybutyrate) (PHB) 106

6.6.2 Polyethylene Adipate (PEA) 109

6.7 Future Perspectives 110

Acknowledgements 110

References 110

7 Optical and Spectroscopic Properties 115

Isabel M. Marrucho

7.1 Introduction 115

7.2 Absorption and Transmission of UV-Vis Radiation 115

7.3 Refractive Index 118

7.4 Specific Optical Rotation 119

7.5 Infrared and Raman Spectroscopy 119

7.5.1 Infrared Spectroscopy 120

7.5.2 Raman Spectroscopy 125

7.6 1H and 13C NMR Spectroscopy 127

References 131

8 Crystallization and Thermal Properties 135

Luca Fambri and Claudio Migliaresi

8.1 Introduction 135

8.2 Crystallinity and Crystallization 136

8.3 Crystallization Regime 140

8.4 Fibers 142

8.5 Commercial Polymers and Products 144

8.6 Degradation and Crystallinity 146

Acknowledgments 148

References 148

9 Rheology of Poly(Lactic Acid) 153

John R. Dorgan

9.1 Introduction 153

9.2 Fundamental Chain Properties from Dilute Solution Viscometry 154

9.2.1 Unperturbed Chain Dimensions 154

9.2.2 Real Chains 154

9.2.3 Solution Viscometry 155

9.2.4 Viscometry of PLA 156

9.3 Processing of PLA: General Considerations 158

9.4 Melt Rheology: An Overview 159

9.5 Processing of PLA: Rheological Properties 160

9.6 Conclusions 165

Appendix 9.A Description of the Software 166

References 166

10 Mechanical Properties 169

Mohammadreza Nofar, Gabriele Perego, and Gian Domenico Cella

10.1 Introduction 169

10.2 General Mechanical Properties and Molecular Weight Effect 170

10.2.1 Tensile and Flexural Properties 170

10.2.2 Impact Resistance 171

10.2.3 Hardness 172

10.3 Temperature Effect 172

10.4 Relaxation and Aging 173

10.5 Annealing 174

10.6 Orientation 176

10.7 Stereoregularity 179

10.8 Self-Reinforced

PLA Composites 180

10.9 PLA Nanocomposites 180

10.10 Copolymerization 181

10.11 Plasticization 181

10.12 PLA Blends 182

10.13 Conclusions 186

References 186

11 Mass Transfer 191

Uruchaya Sonchaeng and Rafael Auras

11.1 Introduction 191

11.2 Background on Mass Transfer in Polymers 193

11.3 Mass Transfer Properties of Neat PLA Films 194

11.3.1 Mass Transfer of Gases 194

11.3.2 Mass Transfer of Oxygen 199

11.3.3 Mass Transfer of Water Vapor 201

11.3.4 Mass Transfer of Organic Vapors 203

11.4 Mass Transfer Properties of Modified PLA 205

11.4.1 PLA Stereocomplex and PLA Blends 206

11.4.2 PLA Nanocomposites 207

11.4.3 Other PLA Modifications 207

11.4.4 PLA in Other Forms 207

11.5 Final Remarks 208

Acknowledgments 208

References 208

12 Migration and Interaction with Contact Materials 217

Herlinda Soto-Valdez and Elizabeth Peralta

12.1 Introduction 217

12.2 Migration Principles 217

12.3 Legislation 218

12.4 Migration and Toxicological Data of Lactic Acid, Lactide, Dimers, and Oligomers 219

12.4.1 Lactic Acid 219

12.4.2 Lactide 224

12.4.3 Oligomers 225

12.5 EDI of Lactic Acid 226

12.6 Other Potential Migrants from PLA 227

12.7 Conclusions 227

References 228

Part III Processing and Conversion 231

13 Processing of Poly(Lactic Acid) 233

Loong-Tak Lim, Tim Vanyo, Jed Randall, Kevin Cink, and Ashwini K. Agrawal

13.1 Introduction 233

13.2 Properties of PLA Relevant to Processing 233

13.3 Modification of PLA Properties by Process Aids and Other Additives 235

13.4 Drying and Crystallizing 237

13.5 Extrusion 239

13.6 Injection Molding 241

13.7 Film and Sheet Casting 245

13.8 Stretch Blow Molding 249

13.9 Extrusion Blown Film 251

13.10 Thermoforming 252

13.11 Melt Spinning 254

13.12 Solution Spinning 258

13.13 Electrospinning 261

13.14 Filament Extrusion and 3D-Printing 265

13.15 Conclusion: Prospects of PLA Polymers 266

References 267

14 Blends 271

Ajay Kathuria, Sukeewan Detyothin, Waree Jaruwattanayon, Susan E. M. Selke, and Rafael Auras

14.1 Introduction 271

14.2 PLA Nonbiodegradable Polymer Blends 272

14.2.1 Polyolefins 272

14.2.2 Vinyl and Vinylidene Polymers and Copolymers 279

14.2.3 Rubbers and Elastomers 285

14.2.4 PLA/PMMA Blends 287

14.3 PLA/Biodegradable Polymer Blends 289

14.3.1 Polyanhydrides 289

14.3.2 Vinyl and Vinylidene Polymers and Copolymers 289

14.3.3 Aliphatic Polyesters and Copolyesters 297

14.3.4 Aliphatic-Aromatic Copolyesters 303

14.3.5 Elastomers and Rubbers 305

14.3.6 Poly(Ester Amide)/PLA Blends 307

14.3.7 Polyethers and Copolymers 307

14.3.8 Annually Renewable Biodegradable Materials 309

14.4 Plasticization of PLA 322

14.5 Conclusions 326

References 327

15 Foaming 341

Laurent M. Matuana

15.1 Introduction 341

15.2 Plastic Foams 341

15.3 Foaming Agents 342

15.3.1 Physical Foaming Agents 342

15.3.2 Chemical Foaming Agents 342

15.4 Formation of Cellular Plastics 343

15.4.1 Dissolution of Blowing Agent in Polymer 343

15.4.2 Bubble Formation 343

15.4.3 Bubble Growth and Stabilization 344

15.5 Plastic Foams Expanded with Physical Foaming Agents 344

15.5.1 Microcellular Foamed Polymers 344

15.5.2 Solid-State Batch Microcellular Foaming Process 345

15.5.3 Microcellular Foaming in a Continuous Process 353

15.6 PLA Foamed with Chemical Foaming Agents 358

15.6.1 Effects of CFA Content and Type 358

15.6.2 Effect of Processing Conditions 359

15.7 Mechanical Properties of PLA Foams 360

15.7.1 Batch Microcellular Foamed PLA 360

15.7.2 Extrusion of PLA 361

15.7.3 Microcellular Injection Molding of PLA 362

15.8 Foaming of PLA/Starch and Other Blends 362

References 363

16 Composites 367

Tanmay Gupta, Vijay Shankar Kumawat, Subrata Bandhu Ghosh, Sanchita Bandyopadhyay-Ghosh, and Mohini Sain

16.1...

| Erscheinungsjahr: | 2022 |

|---|---|

| Fachbereich: | Allgemeines |

| Genre: | Chemie |

| Rubrik: | Naturwissenschaften & Technik |

| Medium: | Buch |

| Seiten: | 688 |

| Inhalt: | 688 S. |

| ISBN-13: | 9781119767442 |

| ISBN-10: | 111976744X |

| Sprache: | Englisch |

| Einband: | Gebunden |

| Autor: | Auras, Rafael A. |

| Redaktion: |

Auras, Rafael A

Lim, Loong-Tak Selke, Susan E M Tsuji, Hideto |

| Herausgeber: | Rafael A Auras/Loong-Tak Lim/Susan E M Selke et al |

| Auflage: | 2nd edition |

| Hersteller: | Wiley |

| Maße: | 286 x 221 x 41 mm |

| Von/Mit: | Rafael A Auras (u. a.) |

| Erscheinungsdatum: | 21.06.2022 |

| Gewicht: | 1,968 kg |